16. September 2016

Industry 4.0 in the milling process: flexible and mechatronic tensioning systems with active vibration damping

Digital networking of the production characterizes the »fourth industrial revolution«. To create the preconditions for the challenges of industry 4.0 manufacturing companies need highly flexible, networked and adaptable production resources. A high potential for productivity increase is in the use of intelligent clamping technique.

For industry 4.0-production not only an effective and efficient information processing is necessary, furthermore the production resources must be physically able to adapt their geometrical form and kinematics flexibly to particular tasks. A constant increase of the product diversity represents a major challenge for the machining production methods, because milling processes get often impaired in their performance by vibrations, especially with long overhanging and thin-walled components.

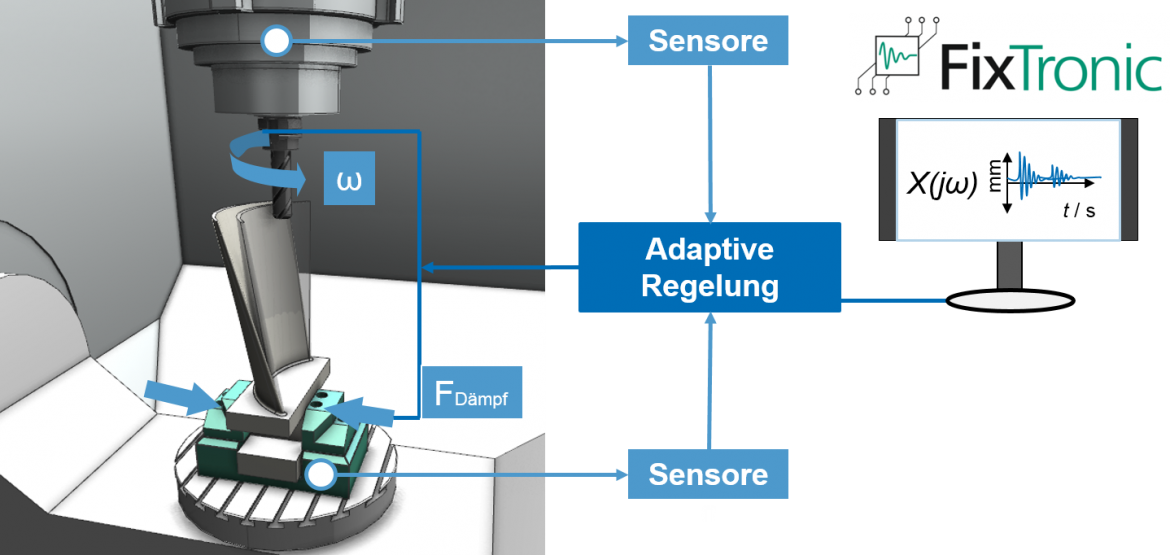

Aim of the research project »FixTronic« is to develop a mechatronic stabilization system, which minimizes process vibrations and instability with an active vibration damping and active speed regulation of the machine spindle: in this way status information of the workpiece get collected by sensors in the tensioning system and get connected with an adaptive regulation. Aimed counter vibrations get induced into the workpiece with piezo actuators, by what vibrations get reduced significantly. The »FixTronic« stabilization system enables in that way the use of efficient process parameters as well as a high quality of production results at the same time. With the adaptive regulation of the system workpieces with different geometry can be clamped and the process reliability is ensured – in result the gap of flexibility in the machining production is filled. The networking of the tensioning system with the machine tool provides an effective process control of the stability performance in the workpiece and allows process reliable work with efficient parameters.

With »FixTronic« the workpiece itself gets a cyber physical system according to industry 4.0 and gets that way an information carrier for the autonomous process control through the product. The project »FixTronic« connects the strengths of different north rhine-westphalian high-tech sites in the field of production and mechatronics, in order to fill the crucial gap of flexibility in industry 4.0.

This project is funded by means of the European Regional Development Fund (ERDF).

Project partners

- CP autosport GmbH, Büren

- Fraunhofer-Einrichtung für Entwurfstechnik Mechatronik IEM, Paderborn

- Fraunhofer-Institut für Produktionstechnologie IPT, Aachen

- Innoclamp GmbH, Aachen

- WBA Aachener Werkzeugbau Akademie GmbH, Aachen