Topics

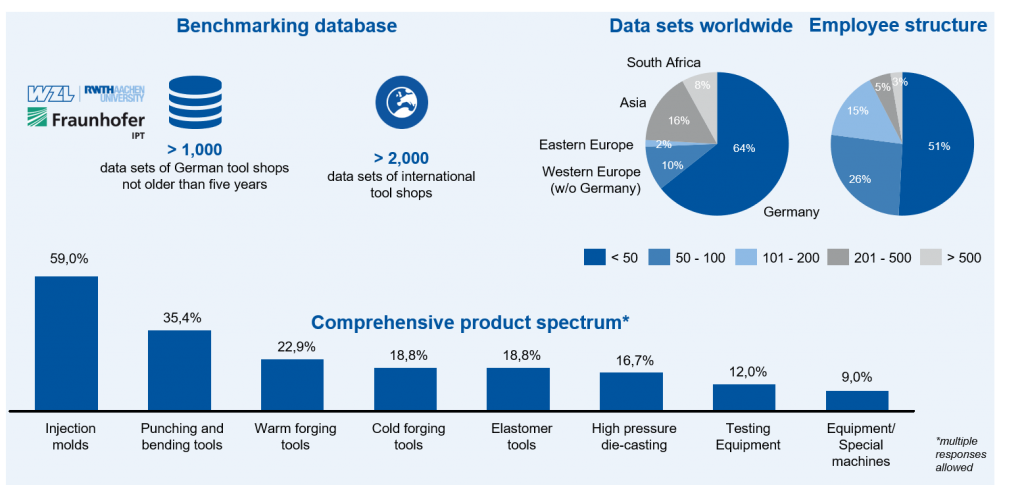

The consulting services of the WBA are focused on the framework conditions and characteristics of the individual and small batch production. The aim is the further development of companies that manufacture tools, moulds, operating resources, equipment and devices for series-producing companies. By constantly taking the specific characteristics of the company into account, an adaption to the individual tool and service spectrum as well as the status quo is ensured.

The range of consulting services is divided into three areas: market and customer, competition and strategy and supporting processes. Due to the modular offer, individual topics from all three areas can certainly be addressed within the scope of consulting projects.

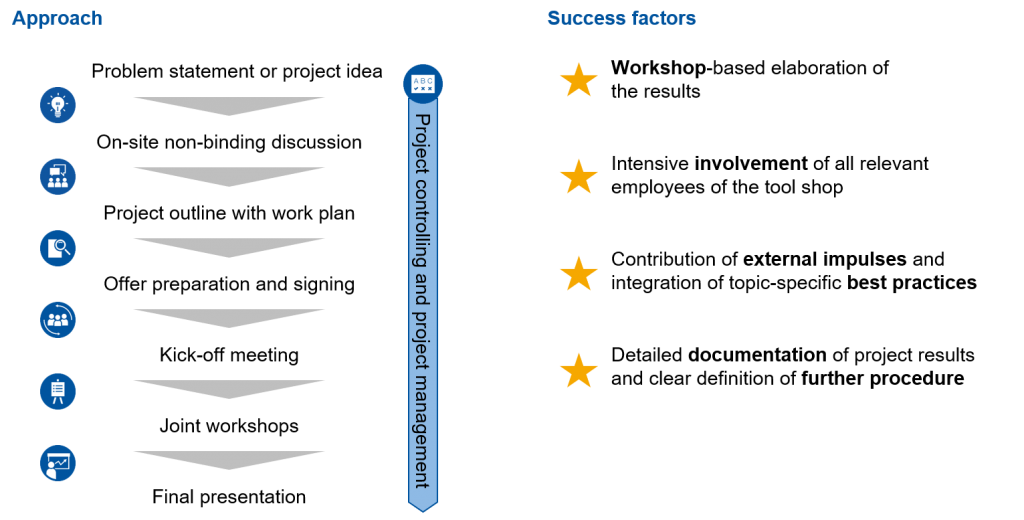

The specific modules of a consulting project are individually defined together with the customer. The use of standard methods, tools and procedures needs to be adapted to the corresponding company conditions. You are welcome to arrange a non-binding appointment with Mr. Christoph Kelzenberg on your premises to discuss your individual situation and to develop an approach that meets your requirements. True to the motto: Uniques in series!